Introduction

I’ve always wondered, that the side supports are very loose while/after stringing teardrop rackets (e.g. Tecnifibre Carboflex). So i tried/strung and measured a lot. After about 12 string jobs, here are my results. The tests were done on a Yonex ES5Protech (6 point self centering mounting system) stringing machine with a cheap (but good) Pros Pro Dura Ace 1,20 mm string. I also strung one time on a Babolat 2502e (Star 4) for comparsion. The results were the same.

I’ve always wondered, that the side supports are very loose while/after stringing teardrop rackets (e.g. Tecnifibre Carboflex). So i tried/strung and measured a lot. After about 12 string jobs, here are my results. The tests were done on a Yonex ES5Protech (6 point self centering mounting system) stringing machine with a cheap (but good) Pros Pro Dura Ace 1,20 mm string. I also strung one time on a Babolat 2502e (Star 4) for comparsion. The results were the same.

Most of the time I used a normal 1 piece bottom up stringjob: with the short side I did the two first strings on the bottom, then I go up with the long side starting at the 3rd cross.

Unfortunately I didn’t test the playability of the string jobs, because I strung them in time of Corona, when the Squash courts were closed.

Why I’m not happy with mains=crosses and do not want to accept it?

Because most of machines have internal main supports which cannot hold the racket properly anymore when it gets longer. Some machines holds the frame inside and from the top like a Prince Neos 1000. But I’m not sure if that is better.

It is also almost impossible to get consistent results if the frame is loose on the machine.

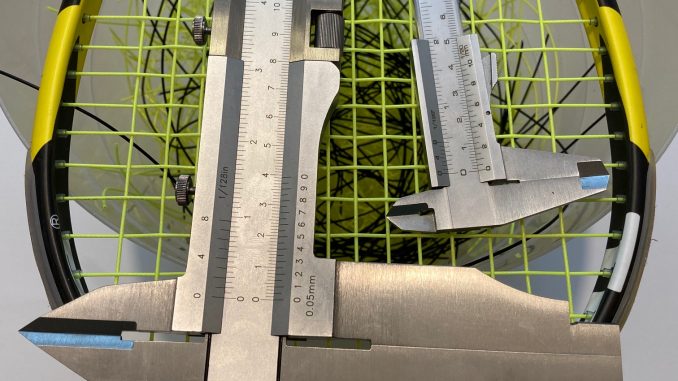

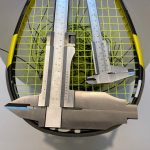

Measurements of the unstrung racket

First of all, I measured an unstrung Tecnifibre Carboflex racket.

First of all, I measured an unstrung Tecnifibre Carboflex racket.

The measurements are:

Length: 323,1 mm

Measure point #1: 215,5 mm

Measure point #2: 141,8 mm

Measure point #3: 115,5 mm

Measure point #4: 105,0 mm

First try

First string job was done with 12 kg on the mains and 12 kg on the crosses. Here are the results:

Length: 324,5 mm (1,4 mm longer)

Measure point #1: 211,8 mm (3,7 mm narrower)

Measure point #2: 137,7 mm (4,1 mm narrower)

Measure point #3: 112,7 mm (2,8 mm narrower)

Measure point #4: 103,2 mm (1,8 mm narrower)

For my understanding 4,1 mm narrower is too much. So i continued the tests.

Results of the stringjobs

| Length | Measure point #1 | Measure point #2 | Measure point #3 | Measure point #4 | ||||||

| unstrung | 323,1 | diff | 215,5 | diff | 141,8 | diff | 115,5 | diff | 105 | diff |

| 12×12 (1P) | 324,5 | -1,4 | 211,8 | 3,7 | 137,7 | 4,1 | 112,7 | 2,8 | 103,2 | 1,8 |

| 12×10 (1P) | 323,7 | -0,6 | 213,1 | 2,4 | 139 | 2,8 | 113,3 | 2,2 | 103,6 | 1,4 |

| 12×8 (1P) | 322,8 | 0,3 | 214,3 | 1,2 | 140,2 | 1,6 | 114 | 1,5 | 103,8 | 1,2 |

| 12×7 (1P) | 322,4 | 0,7 | 214,9 | 0,6 | 141,2 | 0,6 | 114,2 | 1,3 | 104,2 | 0,8 |

| 12×7 (1P)*1 | 322,8 | 0,3 | 214,3 | 1,2 | 140,3 | 1,5 | 114,1 | 1,4 | 104 | 1,0 |

| 12×12 (1P)*2 | 323,3 | -0,2 | 213,6 | 1,9 | 139,9 | 1,9 | 113,6 | 1,9 | 103,7 | 1,3 |

| 12×8 (1P)*3 | 323,1 | 0 | 214,1 | 1,4 | 140,5 | 1,3 | 114,4 | 1,1 | 104,1 | 0,9 |

| 12×8 (2P)*4 | 323,1 | 0 | 214,1 | 1,4 | 140,3 | 1,5 | 113,8 | 1,7 | 104 | 1 |

| 12×11 (2PTD)*5 | 324,7 | -1,6 | 211,5 | 4,0 | 137,8 | 4,0 | 112,2 | 3,3 | 102,9 | 2,1 |

| 12×11 (2PBU)*6 | 324,7 | -1,6 | 211,4 | 4,1 | 138,3 | 3,5 | 112,7 | 2,8 | 103,2 | 1,8 |

| 12×12 (1P)*7 | 324,4 | -1,3 | 212,0 | 3,5 | 137,5 | 4,3 | 112,1 | 3,4 | 102,9 | 2,1 |

- Variable tensions of the mains: 12, 12, 11, 11, 10, 10, 8 and the crosses with 7 kg (1P).

- Normal string job, but only pull every second cross (double pull). Normally a No-Go for good stringers!

- Variable tensions of the mains and crosses: 12, 12, 12, 12, 10, 10, 8 and the crosses with first 2 with double pull, 7, 7 and the rest of the crosses with 8.

- Variable tensions of the mains and crosses: 12, 12, 12, 12, 10, 10, 8 and the crosses top down with 8, … 8, 7.5, 7, 6.5, 6, 5.5, 5, 4.5 ,4

- Normal two piece string job, top down.

- Two piece string job, bottom up.

- One piece UKRSA ATW string job (described in https://theracketsurgery.com/blog/10-ukrsa-atw)

1P means strung in one piece with 2 knots and 2P with two strings and 4 knots. Every time I strung 1P, I strung the racket bottom up. For comparison I strung one racket top down. The result was no really difference between the bottom up.

My result is: If you only look at the distortion, 4 or 5 kg less on crosses is good.

After around 12 stringjobs the racket is still in original shape (+/- 0,2 mm) after cutting the strings off.

Factory strung rackets

In the meantime I also ordered two brand new Tecnifibre Carboflex Airshaft rackets. They are already strung by Tecnifibre/Factory. I measured the tension with Stringmeter from Tourna.

Here is the result:

Mains from left to right: 12, 13, 15, 14, 15, 14, 14 || 14, 16, 15, 16, 15, 13,12

Crosses from top to down: 8, 10, 10, 11, 12, 9, 11, 8, 9, 9, 10, 9, 9, 9, 9, 7, 7, 10

I know, that this tool is not completely correct and imprecise. So I measured it several times to avoid measurement errors. So I strung a reference racket with 9 kg on mains and 7 kg on crosses. The Stringmeter shows between 9 and 9,5 kg on mains and most times 7 kg on the crosses.

So it seems, that Tecnifibre strings his rackets with around 4-5 kg looser on the crosses.

I also measured the dimensions of the racket. The factory strung racket is in a really good original shape:

Length: 0,4 mm shorter

Measure point #1: 0,6 mm narrower

Measure point #2: 1,6 mm narrower

Measure point #3: 1,8 mm narrower

Measure point #4: 0,5 mm narrower

Fun fact:

I got a statement from a Tecnifibre staff and stringer, that Tecnifibre only give warranty if you string the crosses not more than -1 kg. For example: 12/11 kg is allowed and with 12/10 kg you loose the warranty.

Meanwhile I measured some other frames with factory string on it.

Prince Pro Warrior 650:

Mains from left to right: 9, 12, 15, 15, 15, 15, 15, 14 || 14, 15, 15, 14, 15, 15, 13, 11

Crosses from top to down: 9, 10, 10, 10, 10, 10, 10, 10, 9, 10, 11, 9, 10, 12, 11, 11, 11

Dunlop Blackstorm 4D Titanium 3.0 (2018):

Mains from left to right: 13, 16, 15, 14, 14, 16, 11 || 12, 13, 15, 11, 14, 11, 11

Crosses from top to down: 9, 11, 11, 10, 11, 11, 11, 10, 9, 12, 11, 9, 8, 10, 10, 9, 7, 12

Victor Magan Core (cheap Graphite/Aluminum composition):

Mains from left to right: 8, 9, 10, 11, 12, 12, 11 || 11, 10, 10, 9, 10, 9, 8

Crosses from top to down: 7, 9, 10, 10, 10, 10, 9, 9, 9, 9, 8, 8, 7, 7, 7, 7, 7, 7, 8, 8

Wilson Impact Pro 900 (cheap Aluminum composition):

Mains from left to right: 7, 9, 9, 11, 15, 15, 16 || 16, 16, 14, 12, 15, 15, 10

Crosses from top to down: 10, 12, 9, 7, 9, 10, 10, 10, 9, 9, 9, 8, 6, 6, 7, 9, 9, 7, 7

Dunlop Blaze Inferno 4.0 (cheap Graphite/Aluminum composition):

Mains from left to right: 11, 11, 12, 9, 11, 11, 11, 12 || 13, 12, 14, 14, 12, 9, 10, 7

Crosses from top to down: 10, 10, 11, 10, 10, 7, 9, 7, 11, 11, 9, 8, 10, 12, 11, 10, 10,8

Conclusion about factory string: As we see, the factories string the rackets not with equal tensions on mains and crosses. Some have a difference of around 5 kg and at least 2 kg. Is that coincidence or intentional? I think it’s intentional. The last thing the manufacturer wants is to have his racket break quickly.

Friction

One thought was, that the friction on the grommets from the mains is also a huge factor. So i measured it. The machine pulls with 14 kg with constant pull. There is only 12,4 kg left on the string outside the racket. I have also measured inside the racket to exclude the friction of the top grommet. And just to be safe i measured an open throat racket too. First two mains are fine (the friction is from the grommet and shaft). Then the outer mains are more or less the same, than on the teardrop racket.

Conclusion about friction: The friction on most of the squash rackets are huge in the mains, but it seems that is not the main problem. I also strung a racket just as normal with 12×12 kg, but pull the mains on the bottom side with 14 kg instead of 12 kg. The difference in the strung racket was not as big as I thought. Just 0,3 mm shorter than the normal 12×12 kg strung racket and a little bit wider. But the side supports are still very loose in the end of the stringing process.

Friction on the mains at the bottom plays a role, but not a big one.

Interim conclusion

Does it play a role whether we started from top or bottom? I think so. If we still string the teardrop rackets mains=crosses, the racket gets narrower and longer while stringing. So the main and side supports will not hold the racket properly. For my understanding, adjusting the main/side supports while stringing is not an option. The racket sits longer better in the supports when stringing top down. In my view, that’s the main reason why we should string top down.

Updates

Update on 09/07/2020:

– Interim conclusion

– Friction on grommets

– Measured more factory strung frames

Update on 07/07/2020:

– Described used stringing pattern

– After around 12 stringjobs the racket is still in original shape after cutting strings off

– Added 2 two piece string jobs to the table. One top down and one bottom up.

– Added UKRSA ATW string job to the table.

– Measured the factory strung Tecnifibre Carboflex 125 Airshaft with an unstrung.